Gallery

RPM’s Mechanical division has a broad range of services that operates to site / client needs.

RPM services, maintains and refurbishes fixed plant equipment from crushing, screening and conveying equipment including full hydraulic, pneumatic, condition monitoring, geared motors, heavy industrial gears and electrical and instrumentation to site / client needs.

Please contact us to discuss your needs.

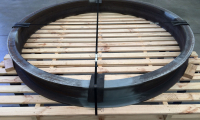

A secondary crusher feed chute fully fabricated, surface coated and wear plate lined by RPM. Then site fitted for a new large tonne gold operation.

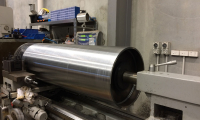

Fully manufactured by RPM, a secondary crusher support frame, surface coated then site fitted for a new large tonne gold operation.

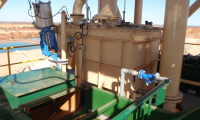

Fully manufactured by RPM a conveyor head chute, including surface coatings, wear linings and assembly then site fitted with drive unit and commissioned for a large gold operation.

RPM fully manufactured to site specifications, a distribution boiler box including surface coatings, rubber lining then site fitted for a large gold operation.

Fully manufactured to site requirements by RPM, pipe spools, piping including full weld testing and galvanising for Cape Preston. RPM can carry out pipeworks and surface coatings to client requirements including rubber lining.